Propeller innovation has come a long way, bringing center console boats new levels of performance, efficiency, and handling on the water. Today’s new marine prop tech—from premium stainless to advanced composites and Sharrow® loop-blade designs—delivers quicker planing, cleaner mid-range efficiency, and better grip in the chop. Here at Black Label Marine Group, our service department delivers on all fronts of center console performance.

Key takeaways

- Material and blade geometry drive holeshot, cruise MPG, and handling.

- Stainless, composite, coated/hybrid alloys, and Sharrow each solve different saltwater challenges.

- Sea-trial the finalists on the same day, same load, and log RPM, speed, and GPH.

Saltwater materials that matter

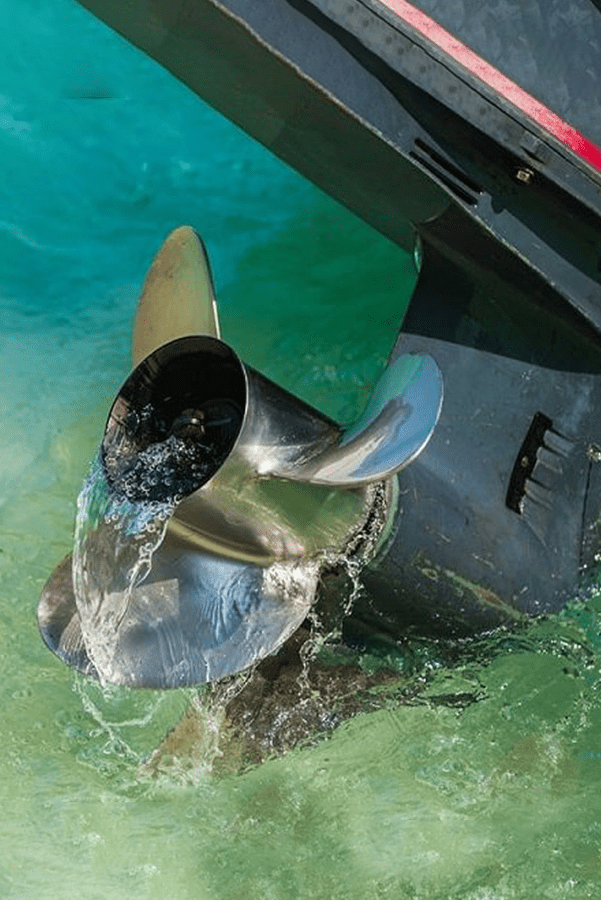

Stainless steel (3- and 4-blade)

Why it works: High strength lets blades stay thin and sharp for strong bite and stable edges at speed.

Best for: Heavier or high-HP center consoles; frequent offshore runs.

Trade-offs: Heavier than composites; needs a prop shop for repairs.

Advanced composite (including reinforced polymers)

Why it works: Light weight and tuned flex give fast spool-up and quiet running; no rust or galvanic worries.

Best for: Inshore/bay boats, family duty, and shallow water where the occasional bump happens.

Trade-offs: Ultimate stiffness and top-end may trail premium metals on heavy rigs.

Coated / hybrid-alloy metal

Why it works: Stainless or alloy cores paired with hard coatings to slow pitting and edge wear in salt.

Best for: Versatile boats splitting time between sandbar and offshore.

Trade-offs: Quality and repairability vary by brand; confirm local service.

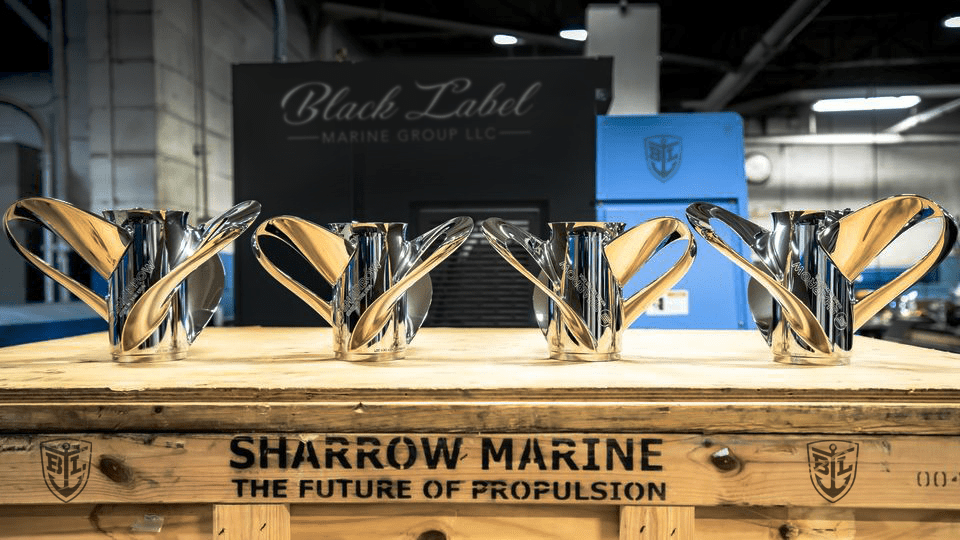

Sharrow® loop-blade designs

Why it works: The Sharrow has a distinct looped blade geometry that increases low-speed thrust and reduces slip, helping many boats plane sooner and hold speed at lower RPM making it one of the most ideal center console propellers.

Best for: Owners chasing maximum holeshot and mid-range efficiency without giving up comfort.

Trade-offs: Premium price; sizing is application-specific, so a proper fit is essential.

Quick comparison

| Need | Stainless | Composite | Coated/Hybrid Metal | Sharrow® |

|---|---|---|---|---|

| Holeshot / Bite | Very good | Good on light boats | Very good | Excellent |

| Cruise Efficiency | Very good | Good | Very good | Excellent (many setups) |

| Top-End Speed | Very good | Fair–Good | Very good | Very good |

| Saltwater Durability | High | Inert (no rust) | High | High |

| Serviceability | BLMG | Often modular blades | BLMG | BLMG |

How to choose (rigging checklist)

- Define the job: Heavy offshore loads → stainless or coated/hybrid. Light, shallow, or family use → composite worth a look.

- Hit WOT spec: Prop to your outboard’s recommended full-throttle RPM. It’s the fastest path to better speed and MPG.

- Dial the geometry: Pitch, diameter, rake, and cup must match your hull and engine height. A stiffer prop sometimes lets you drop pitch ½–1″ for stronger launch.

- Plan for service: Know who can true, balance, or swap blades locally. For Sharrow, talk to rigging experts at Black Label Marine Group

Ready to feel the difference?

Want your boat to run better? Black Label Marine Group will help you select the proper center console propeller for your needs—whether that’s premium stainless, advanced composite, coated/hybrid metal, or a Sharrow® option. We look at your hull, engine model, typical load, and how you run, then match center console propellers from today’s new marine prop tech to your goals for holeshot, cruise efficiency, and comfort.

Once you’ve picked the prop, our rigging and service experts handle the install with care: correct hub and hardware, torque to spec, balance and clearance checks, and an engine-height review to help your setup run smooth and efficient in saltwater. Ready to upgrade your performance—reach out to our service team today.

FAQ

On mid-size center consoles with moderate loads—yes. For big crews or constant bluewater runs, metal or Sharrow usually holds bite better.

No. Many rigs see improved mid-range efficiency and the ability to hold plane at lower RPM, which reduces fuel burn and noise.

Not always, but saltwater use demands materials and coatings that resist corrosion. Stainless and coated/hybrid props hold up best offshore, while composites avoid rust entirely.

Inspect your prop at least every season—or sooner if you notice vibration, dings, or loss of performance. A damaged or worn prop can cost you speed, fuel, and even strain your engine.